The Transition to Software Barcode Scanning

The way businesses approach barcode scanning is evolving. Traditionally, barcode scanning relied on dedicated hardware—fixed scanners, handheld barcode readers, and proprietary scanning modules. These devices, while effective, often come with high costs, limited flexibility, and challenges in integrating with modern automation systems.

Now, with advancements in computer vision and edge processing, software barcode scanning has become a viable, scalable, and cost-effective alternative. By leveraging standard cameras and powerful processors, businesses can build mobile and automation solutions that are more open, adaptable, and future-proof—often at a lower cost.

Why Transition Away from Dedicated Barcode Scanners?

For decades, barcode scanning was dominated by purpose-built hardware products, often locked into proprietary ecosystems. While these devices were designed for enterprise reliability, they came with inherent drawbacks:

- High Cost – Dedicated barcode readers, especially those designed for industrial environments, can be very expensive.

- Limited Flexibility – These devices are often specialized, making it difficult to adapt them for new use cases or integrate them with emerging technologies.

- Limited Upgradability & Fast Obsolescence – Dedicated barcode scanners are closed systems, making it difficult to upgrade hardware or software as technology advances. Given their long design cycles, these devices often risk being outdated before they even launch, lacking the flexibility to adapt to evolving business and automation needs.

- Single-Sourcing Risks – Dedicated barcode scanners lock businesses into a single supplier, creating dependencies that can lead to supply chain disruptions, price increases, and limited flexibility. Integrating alternative hardware is often difficult, giving the supplier effective control over customer solutions.

- Complex Networking & Integration – Many legacy barcode scanners do not easily integrate with modern software systems, requiring additional middleware or proprietary protocols.

By contrast, software-based barcode scanning eliminates these constraints, allowing businesses to build scanning solutions with standard cameras, edge computing devices, and open software platforms.

The Power of Software Barcode Scanning

Software barcode scanning enables businesses to use almost any camera—ranging from low-cost embedded modules to high-resolution industrial cameras—to capture and decode barcodes (see the camera choice Whitepaper). This shift brings several advantages:

- Hardware Choice & Scalability

Unlike dedicated barcode scanners, which have limited model variations, software scanning can run on a wide range of imaging hardware:

- Smartphone Cameras – Ideal for mobile workers or retail applications.

- Embedded & USB Cameras – Found in kiosks, point-of-sale systems, and portable scanning devices.

- Industrial Cameras – Used in logistics, warehousing, and robotics for high-resolution, high-speed scanning. (See Whitepaper on choosing cameras)

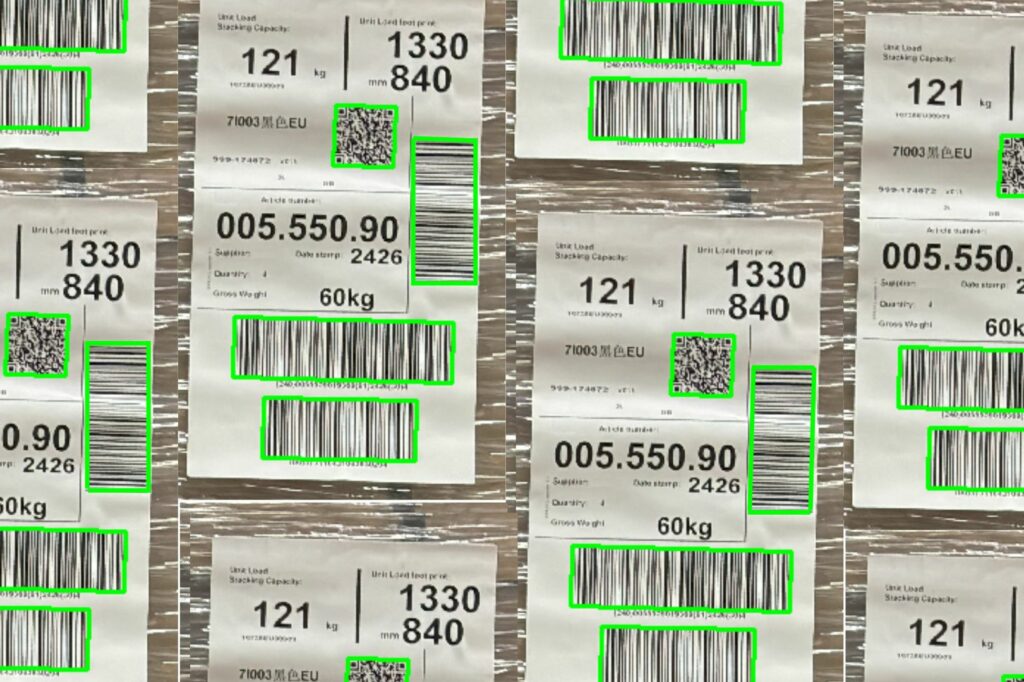

For example, 20MP and up industrial cameras can capture wide areas and multiple barcodes at once (using Maxi-Scan), something not easily achievable with traditional barcode scanners.

- Cost Savings & ROI

Using off-the-shelf cameras instead of specialized barcode scanners results in significant cost savings. Businesses can select hardware based on budget and performance needs, avoiding the high markup of dedicated scanning devices. Second sources can be specified to avoid price increases and supply chain disruptions. New or upgraded components can be designed in to improve the solution.

Additionally, software barcode scanning can be deployed on existing infrastructure—such as smartphones, tablets, or camera-equipped robotic systems—further reducing hardware investment.

- Multi-Functionality & Future-Proofing

Software-based scanning opens the door to continuous improvement and advanced machine vision applications beyond barcode reading. With a camera-based system, businesses can:

- Improve existing solutions by upgrading versions.

- Expand item recognition to include OCR—reading the text on labels and packaging.

- Use AI/ML for defect detection and object recognition.

- Capture video evidence for process validation.

- Integrate additional vision-based automation and quality tools.

This makes the transition to software barcode scanning not just a cost-saving measure, but a step towards broader automation and smart data capture.

Real-World Applications

Many companies have already embraced software-based barcode scanning for greater flexibility and performance:

Autonomous Robots & Drones

The doks inventAIRYXL warehouse inventory solution, powered by Viziotix, is a perfect example. This drone-based system uses onboard high-resolution cameras to scan barcodes, eliminating the need for manual inventory counts and increasing warehouse efficiency. (See the Case Study)

Forklift-Mounted Scanners

Instead of installing multiple fixed scanners throughout a warehouse, OEMs, such as Ware-ID Free Scan, (see the Case Study) and logistics companies are integrating software scanning on forklift-mounted industrial cameras. This allows real-time barcode capture without stopping operations.

Gate or Dock Scanners

Automatic traceability in the warehouse is being enhanced with gate scanners on the docks or preparation areas to ensure that every pallet is captured as it is shipped or received. Cameras mounted either side of the dock door capture both barcodes and images for the ultimate confidence in WMS data. See the doks gate scanner

Retail & POS Systems

Retailers are integrating barcode scanning SDKs into smartphone applications for associates and self-checkout, and also into fixed hardware such as POS terminals and checkout kiosks, reducing hardware costs and improving system flexibility. A simple way to integrate barcode scanning into a process is to implement a keyboard wedge software scanner into a mobile device. This way, no coding is necessary to start using barcode scanning with a wide variety of applications. MobXscan is one of these keyboard wedge applications.

Storage Systems in Retail & Logistics

Automated storage and retrieval systems speed the delivery of the correct items to consumers in retail and to operators in manufacturing and logistics. The accuracy of these systems is provided by networks of cameras that use barcode scanning SDKs to scan items as they are loaded, stored and picked for delivery. In retail pharmacies, Mekapharm automates the storage and delivery of medicines to improve the accuracy and efficiency of its retail clients – See the Alpha Sorter case study.

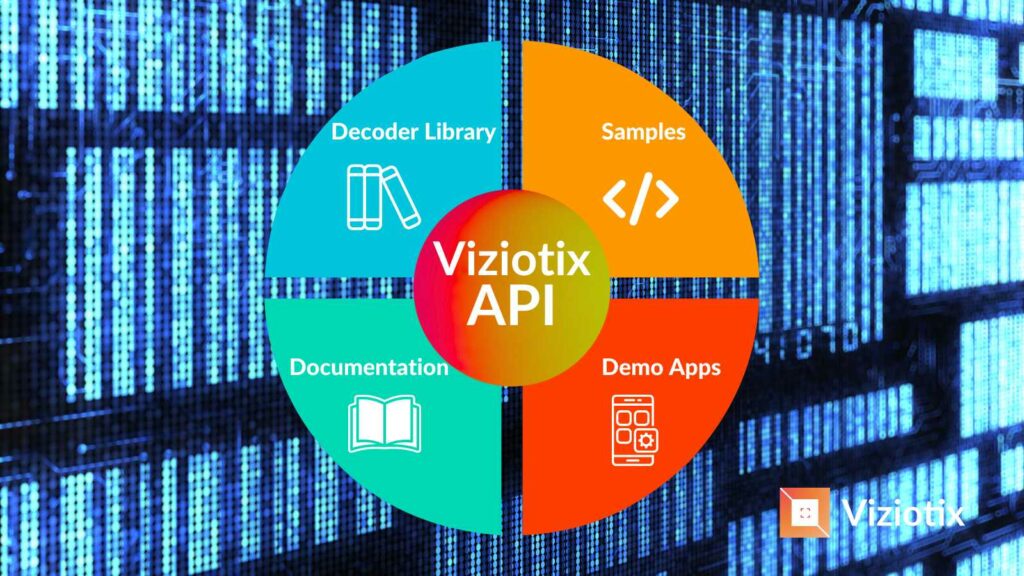

Making the Transition to Software Scanning

Transitioning from dedicated barcode scanners to software-based solutions is not just about cutting costs—it’s about creating a flexible, scalable system that adapts to future needs. By leveraging open hardware and powerful barcode scanning SDKs like Viziotix’s, businesses can achieve greater control over their automation solutions.

Once the system is built, the open architecture can be leveraged to improve existing functionality and to add new software technology. The speed of advance in software is such that buying closed propriety hardware is ensuring an out-of-date solution—perhaps before it is even implemented!

If you’re interested in learning more about how software-based barcode scanning can work for your application, get in touch with us today! If your already convinced, then download our SDK and start building your new software-based barcode scanning solution right now!