Automated Barcode Scanning on Forklifts - Ware-ID Free Scan

How Ware-ID’s “Free Scan” forklift-mounted scanner eliminates manual scanning.

Ware-ID SAS, headquartered in Normandy, France, specializes in developing advanced automation solutions for warehouses and logistics operations. One of their key innovations, the Ware-ID “Free Scan”, is an automated barcode scanning system designed to track and trace pallets efficiently. This system is mounted onto the front of forklifts to enhance safety and workflows. Integrated seamlessly into the forklift frame, the solution operates autonomously, eliminating the need for manual handling or traditional handheld scanners. Operators no longer have to dismount from the forklift to scan, reducing the risk of injury, enhancing comfort, and streamlining overall operational efficiency.

In 2024, Ware-ID equipped more than 400 forklifts with Free Scan and scanned more than 20 million barcodes in warehouses with a read rate over 96%. Ware-ID’s Free Scan increases productivity in logistics processes by 5%, for operations such as receiving, stocking, pallet preparation and dispatch.

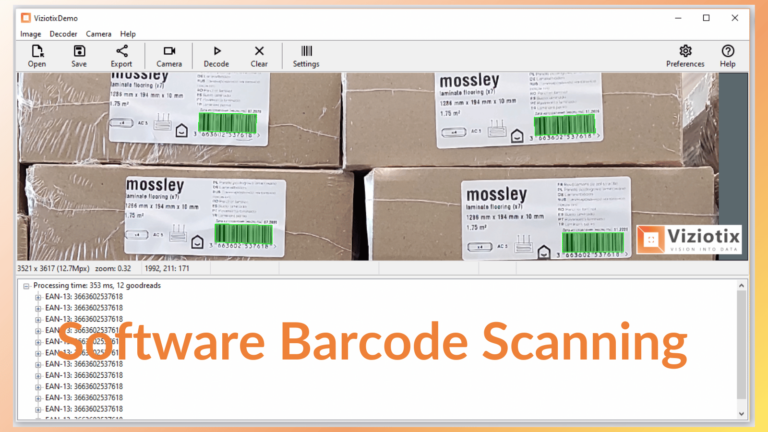

Free Scan uses integrated cameras streaming images to the Linux based embedded computing unit. The images are then processed by Viziotix machine-vision algorithms that detect, decode and transmit the barcode data to the Free Scan microcontroller. The barcode data is then immediately sent to the WMS (Warehouse Management System).

Free Scan enables the identification of pallets with item barcodes or pallet labels, SSCC codes (Serial Shipping Container Codes), and rack location barcodes, for receiving, putaway, picking and loading operations in warehouses.

The key results of this integration are:

The Problem

The warehouse is a challenging environment for barcode scanning. Forklifts are always on the move and can reach speeds of up to 10km/hr. Forklift camera images may therefore be blurred by this movement or associated vibration. Barcodes can be found anywhere on the pallet and may be damaged or covered by plastic wrap, making them challenging to find and decode. As a result, achieving a high barcode read-rate is a crucial challenge for any automation solution.

The second issue is the time to read. It is important that barcode scanning is a seamless part of the process and does not add additional time, or require manual rework, that impacts overall operational efficiency.

Lastly, the safety of forklift operators and warehouse workers is paramount. If manual scanning or rework is necessary, then operators may have to dismount from forklifts to scan, or involve other warehouse workers with handheld mobile devices and this puts them at risk of moving equipment.

The Solution

Ware ID integrated the Viziotix Barcode SDK into Free Scan with the Nano-Scan algorithm enabled. Nano-Scan is a machine-vision technology that overcomes the problems of blurred images to scan barcodes. Most decoders require 3 to 5 pixels per bar to read a barcode, whereas Nano-Scan needs less than 1 pixel per bar (called “sub-pixel” resolution). This innovation compensates for the blur created by a forklift’s speed and vibration. Images with movement blur lose resolution as the bars of the barcode merge together in the image making them impossible to read without Nano-Scan

The Nano-Scan algorithm almost doubles the read range, allowing Free Scan to read SSCC codes from over 1 meter away—compared to the 60–70 cm limit of other barcode scanning SDKs. This extended range saves time during putaway and picking processes, as operators can scan pallets without stopping or slowing the forklift, enhancing both efficiency and user comfort.

Often SSCC code labels are placed anywhere on a pallet side and therefore may not be centered in the image. This problem is resolved by Viziotix Smart-Findr, a high-speed algorithm that detects barcodes anywhere in large images.

With Viziotix, it only takes a few milliseconds to find and scan one barcode anywhere in an image and an average of only 200ms to read 50 or 100 barcodes in a high-resolution image of 12Mpx (please refer to Viziotix Maxi-Scan algorithm to learn more about decoding many barcodes per image).

As a result, the complete process consisting of finding a barcode, decoding it, transmitting it to the WMS and checking and validating the data has been reduced by 50% compared to previous SDKs! From 2 seconds on average, Free Scan now takes less than a second to identify and process a pallet’s data. This is additional to the time already saved in moving from manual scanning to the automated Free Scan solution.

The advanced Viziotix SDK is engineered to deliver exceptional scanning success rates, even in the most challenging conditions. It reliably reads damaged, low-contrast, distorted, poorly printed, high-resolution, on-screen, colored, or reversed barcodes, with performance continually enhanced in every new version release.

By implementing Viziotix software, Ware-ID has achieved a scan success rate exceeding 96% with Free Scan, fully satisfying customer requirements.

“Viziotix’s barcode scanning SDK enabled us to achieve a scan success rate of over 96% in the warehouse, while reducing pallet processing time to 1 second or less with Free Scan. We also selected Viziotix for their exceptional technical support, as they consistently respond within 24 hours.”

Nicolas David, CEO Ware-ID

The Results

After fully integrating Viziotix into Free Scan, Ware-ID reduced barcode scanning and pallet validation time by 50%. The scanning success rate increased from below 90% with other SDKs to over 96%. Forklift operators can now perform tasks such as putaway and pallet picking without slowing down, ensuring a seamless and user-friendly scanning process.

- The complete pallet scanning and validation process time has been reduced from 2 seconds to less than 1 second

- The barcode scanning success rate on moving forklifts averages more than 96%

- Due to the scanning speed and Nano-Scan, forklift drivers no longer need to slow down or modify their driving to adapt to automated scanning

For more details on this case or general information on Viziotix, please contact us: